Know Your Shapes – What Is a Steel Beam?

Steel beams are the backbone of our society. In fact, when you see a non-residential building, you’re surrounded by structural steel beams. Did you know, the modern method of producing beams (rolled from a single piece of steel) was patented by Alphonse Halbou back in 1849? In fact, it is still the structural steel of choice for hundreds of thousands of buildings around the globe.

The shape of the beam makes it an ideal choice for unidirectional bending parallel to the web. In addition, the horizontal flanges resist the bending moment while the web resists shear stress. Often called an I-beam (since, when it is vertically supporting a load, it looks just like the letter “I”), it is one of the most efficient shapes to use. For instance, the beam uses the least amount of steel per foot for a variety of applications.

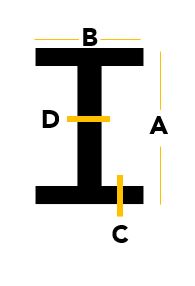

Steel Beam Diagram

Beam Depth: The distance from the top and bottom surface of the steel (see “A” in diagram).

Flange Width: The top and bottom flat horizontal sections width (“B”).

Flange Thickness: The thickness of the top and bottom flat horizontal sections (“C”).

Web Thickness: The thickness of the vertical center section of a steel beam (“D”).

Fillet radius: The curved portion, where the inside transition between the web and flange occurs is called a fillet. The radius of the fillet is called the fillet radius (not always provided).

What makes up a beam? First, the top and bottom (the flat, horizontal section) of the “I” are known as “Flanges”. Next, the middle portion (or I) is called the “Web”. Did you know, your web is what resists the shear force, while the flanges resist most of the bending moment experienced?

How to Order a Steel Beams

Do you know how to order a wide flange beam? As an example, you have a drawing from your engineer that calls out a W27 x 178 that is 30 feet long. Next, you call up a local metals distributor (including Contractors Steel who stock tens of thousands of tons of beams at four stocking locations in the Midwest). Then, you say “I’m looking for a 27 @ 178 x 30 foot long”. That means you want a 27” web (the middle part of the I) thickness from end to end (that is actually 27.81” from the two outer edges). Then, the 178 refers to the weight per foot of the beam x a 30 foot long piece. Therefore, that one-piece weighs 5,340 lbs (or, more than 2.5 tons)!

To look further at the beam, the flange is 14” wide, but the actual dimensions (when measured from end to end is 14.085”.

The thickness of that flange would be 1.19” thick (which can be done with a standard tape measure):

And the thickness of the web (the middle portion of the I) is .75”:

Steel Beam Specifications

Depending on the application, you’ll order standard or wide flange beams to an ASTM specification. The most common is ASTM A36, which has a min yield of 36 KSI, a tensile range of 58-80 and an elongation of 21. Furthermore, other common beam specs include ASTM A709 and ASTM A992. In fact, all beams that are purchased through a service center should come with an MTR, or Material Test Report. MTRs show the chemical composition of the steel used to manufacture the beam. In addition, they also contain the yield, tensile and elongation properties.

Partnering with Contractors Steel

Did you know, when you partner with Contractors Steel, you have access to ALL of our processing capabilities? This includes:

- Plate processing, including laser and oxy fuel

- Coil Leveling

- Press braking

- Sawing

- Angle Master

- T-Splitting

- Plate Rolling

- And More

In conclusion, we stock a complete line of ASTM A36 beams from 3 x 5.7 through 36 x 231? Contact us today for any quantity!